The last review I did of this trial asked the question - Can Yorkshire deliver any stressful climatic conditions? That answer to that is no (not yet anyway).

So we're going to add some artificial stress - just like managing turf - with wear.

What stresses can we control?

Since Yorkshire isn't renowned for its high levels of drought, heat or sunshine we are imparting the stresses we can control - wear.

The video above shows the wear machine in action. We have doubled the amount of this to help show the benefits of our Biostimulant and the Primo treatments in this trial.

Whilst this machine is replicating foot traffic that's not the only wear or stress being imparted on your turf.

The maintenance program at STRI is fairly low - only 3 cuts per week. I'd imagine most courses now have at least 7 operations a week taking place on greens. That's before verticutting, topdressing, rolling plus the additional wear of clean up cuts, etc.

Management operations are often underestimated as a stress factor. Whilst all of the operations you undertake are key factors to improving putting surfaces they often add additional stress.

I wouldn't recommend reducing these operations - just be conscious of how much negative impact they can have on fine turf when imposed on top of other stressful conditions.

I'm sure you've all seen weak collars on greens where rollers consistently change direction in the same place, triplex rings showing additional damage in shaded corners of greens or damage imparted from rolling after topdressing.

A little bit of consideration and thought about which operations can be reduced often goes along way to improving plant health:

- Do you need to cut the green perimeter daily?

- Can you replace a perimeter cut with a hand mown perimeter cut?

- Do you need to verticut the whole green (can you lift up over weak areas?)

- Can you remove a cut and replace with a roll?

- Can you change the direction of a roll operation to spread the wear around the collar?

These aren't always easy or even possible, In turf management - failing turf rarely is caused by one factor - its generally a combination. In an environment where stresses add, you are in control of many of them and a bit of consideration could make the difference.

And what else have we learned from the trial results?

Rather than showing you graphs that haven't changed I thought I'd talk a little about the GDD windows and what's happening.

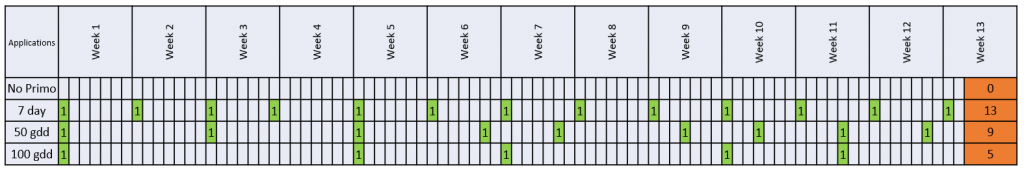

The above table shows all of the applications of Primo since the trial commenced. You can see that the:

- 7 day applications have happened at a very regular frequency

- 50 GDD applications started around 14 day intervals and have now tightened to approx 7 days

- 100 GDD applications started around 28 days and have now tightened down to approx 12 days

Now we are in the full flow of the Yorkshire summer we are seeing very little difference between all these Primo application timings in the turf quality and turf colour figures. This makes complete sense because the timings are all now pretty close to each other.

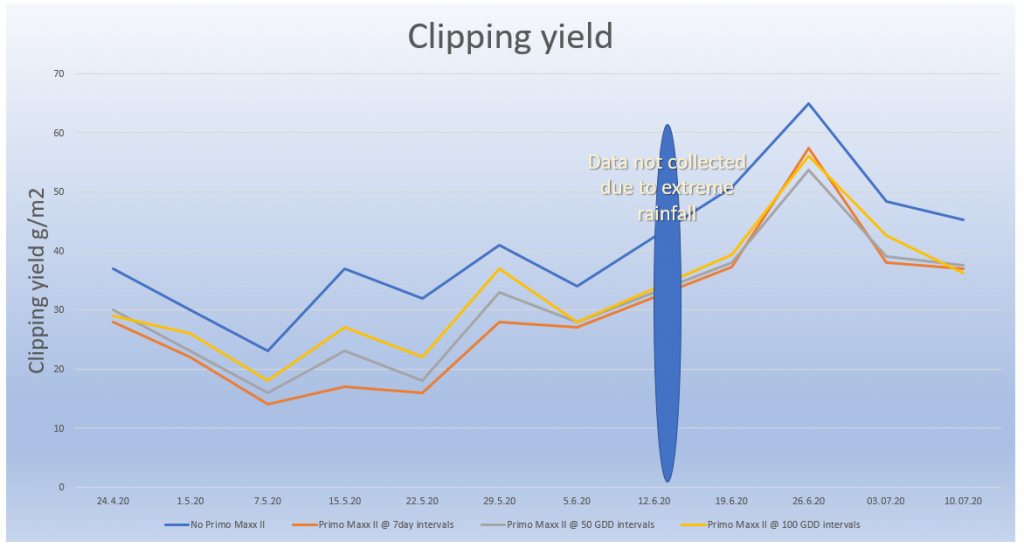

The above graph shows that even clipping yield now is not benefitting from the early additional applications.

So what's the advantage to using GDD?

Here we are in the middle of summer and the 3 GDD programmes are showing very little difference. How many applications have we made?

- 7 day intervals 13 applications

- 50 GDD intervals 9 applications

- 100 GDD intervals 5 applications

The benefit to those additional applications was the larger amount of growth suppression in the Spring - something that in a normal year probably isn't that helpful when trying to achieve a consistent putting surface. However in this unusual year (that we hope we never see again) the extra growth suppression was very helpful.

Don't get too hung up on exact intervals - check this blog out to see why I think applications between 100 and 150 is about right.....